Introduction to Plasmavac

Plasmavac is a UK-based plasma coating company specializing in PVD (Physical Vapour Deposition) technology to apply exceptionally durable and decorative metal finishes to a wide range of materials and products. Our advanced vacuum coating machines are engineered to deliver high-quality finishes using cathodic arc deposition and magnetron sputtering technologies.

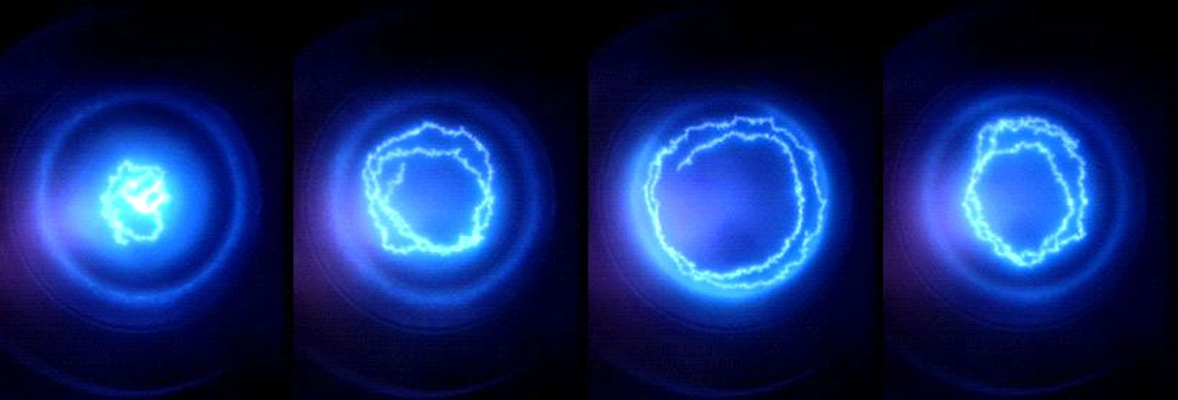

During the coating process, the chosen target metal (the material used for the coating) is evaporated into a metal ion plasma through electrical arc evaporation within a vacuum chamber. The resulting metal ion mist is then attracted to the items being coated. It condenses and chemically bonds to the product's surface, creating a highly durable finish with excellent adhesion and striking visual appeal.

What We Can Coat:

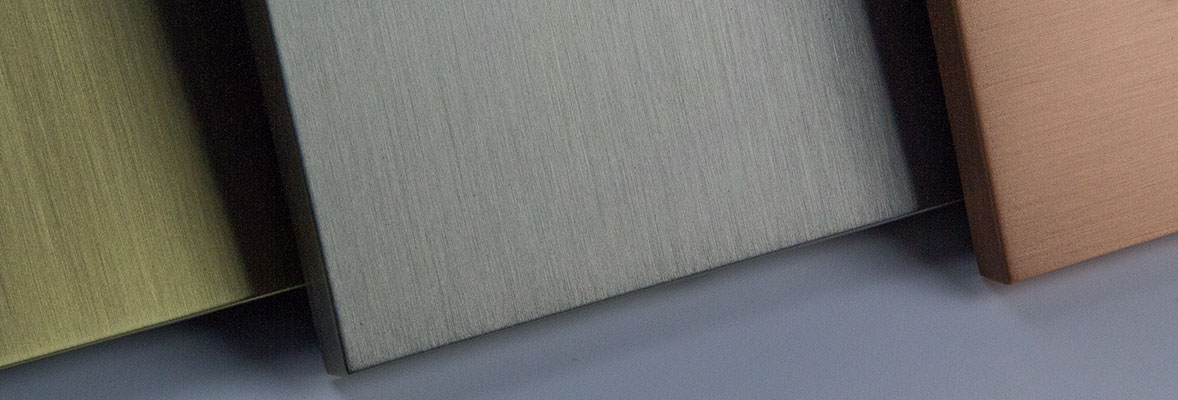

Plasmavac can apply a variety of decorative finishes, including mirror-polished, satin, matte, and brushed textures. These finishes can be applied to materials such as stainless steel, ceramic, and glass. With proper preparation, we can also coat steel, brass, aluminum, and certain plastics.

Our Range of Finishes:

We offer an array of stunning decorative metal finishes, including chrome, gold, rose gold, antique gold, brass, nickel, black chrome, and copper. Additionally, we continually develop new, hard-wearing colored finishes through our in-house research and development team.

Eco-Friendly Technology:

Our high-tech metal coating process represents the latest in green technology. It is a safe, chemical-free alternative to traditional electroplating, which involves hazardous chemicals that are difficult to recycle and harmful to the environment.

Applications:

Plasmavac's decorative PVD coatings are perfect for a wide range of applications, including:

Interior and home design items such as bathroom products and accessories

Sports equipment

Marine fittings

Car parts and leisure goods

Eyewear

Shop fittings and fashion accessories

Kitchenware

Luxury goods requiring durable and visually appealing metal finishes

Here at Plasmavac we are happy to deal with all sorts of projects and products from a large production run right through to a smaller single order, if you need to discuss your project please call 01722 638338

During the coating process, the chosen target metal (the material used for the coating) is evaporated into a metal ion plasma through electrical arc evaporation within a vacuum chamber. The resulting metal ion mist is then attracted to the items being coated. It condenses and chemically bonds to the product's surface, creating a highly durable finish with excellent adhesion and striking visual appeal.

What We Can Coat:

Plasmavac can apply a variety of decorative finishes, including mirror-polished, satin, matte, and brushed textures. These finishes can be applied to materials such as stainless steel, ceramic, and glass. With proper preparation, we can also coat steel, brass, aluminum, and certain plastics.

Our Range of Finishes:

We offer an array of stunning decorative metal finishes, including chrome, gold, rose gold, antique gold, brass, nickel, black chrome, and copper. Additionally, we continually develop new, hard-wearing colored finishes through our in-house research and development team.

Eco-Friendly Technology:

Our high-tech metal coating process represents the latest in green technology. It is a safe, chemical-free alternative to traditional electroplating, which involves hazardous chemicals that are difficult to recycle and harmful to the environment.

Applications:

Plasmavac's decorative PVD coatings are perfect for a wide range of applications, including:

Interior and home design items such as bathroom products and accessories

Sports equipment

Marine fittings

Car parts and leisure goods

Eyewear

Shop fittings and fashion accessories

Kitchenware

Luxury goods requiring durable and visually appealing metal finishes

Here at Plasmavac we are happy to deal with all sorts of projects and products from a large production run right through to a smaller single order, if you need to discuss your project please call 01722 638338